HDP TST Digital Three Side Trimmer represents a shift towards a fully autonomous bindery. By combining zero-makeready technology with robust digital connectivity.

|

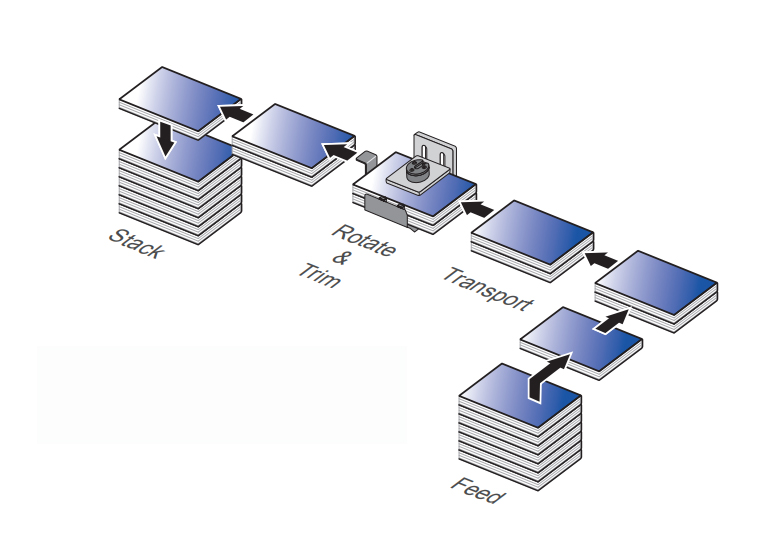

In the rapidly evolving landscape of book production, the transition from mass production to "book-of-one" workflows has created significant pressure on post-press departments. While digital print engines have mastered variable data, traditional finishing equipment often lags behind, creating bottlenecks with lengthy setup times. The HDP TST Digital Three Side Trimmer addresses this critical gap with its engineered zero-makeready capabilities. By eliminating the mechanical downtime associated with format changes, this robust system allows print service providers to seamlessly transition between varying book sizes without interrupting the production flow. The core of this efficiency lies in the machine's advanced integration of barcode scanning and JDF workflow connectivity. As each book block enters the trimmer, the system scans a unique code that instantly communicates the precise trim dimensions and job specifications to the machine. This data-driven approach removes the need for manual adjustments, allowing operators to mix different formats in a single production run. Whether processing a single personalized photo book or a short run of manuals, the HDP TST adjusts automatically, ensuring that the finishing pace matches the speed of digital output.  Beyond mere speed, the system's automated pile rotation utilizing single-knife technology significantly reduces the machine's physical footprint while maintaining high throughput. Unlike complex multi-knife systems that require extensive tooling changes, the single-knife design rotates the book block for each cut, managed by precise servo controls. This smart engineering ensures that every side is trimmed to exact specifications, maximizing floor space efficiency without sacrificing performance.  For digital printers, this level of automation translates directly to profitability. The ability to handle "book-of-one" orders without the cost penalty of setup time transforms short-run jobs from a logistical headache into a high-margin opportunity. The HDP TST supports unattended operation, allowing businesses to reallocate skilled labor to other high-value tasks while the machine reliably handles the repetitive work of trimming.  Ultimately, the HDP TST Digital Three Side Trimmer represents a shift towards a fully autonomous bindery. By combining zero-makeready technology with robust digital connectivity, it provides the agility required to compete in the modern on-demand marketplace. It is not just a cutting tool; it is a strategic asset that synchronizes the final stage of production with the dynamic nature of digital printing. |

| Tag:Digital Three Side Trimmer,HDP TST,digital finishing,three side trimmer,post-press |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!